Wastewater treatment

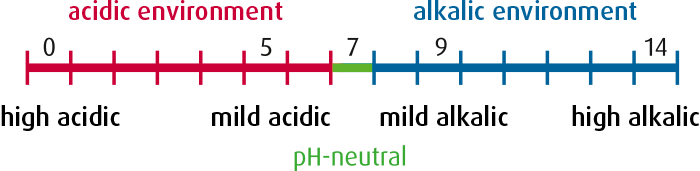

For waste water treatment in your car wash, we recommend using process water with a pH value of 7-8 for cleaning. For rinsing, it is best to use permeate water. In this way, you reduce your water consumption and have an ecological and high-quality sales argument for your customers.

The subject of water is an important variable in our modified understanding of Sinner’s circle, because only with high-quality water can you achieve an unobjectionable cleaning and rinsing performance.

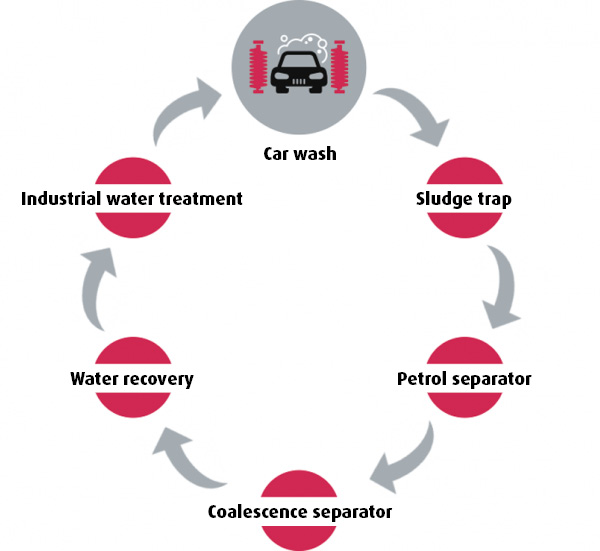

Due to the economic burden caused by high freshwater consumption, car wash operators have increasingly turned to internal water treatment in recent years and decades.

Today, as a rule, no new plant is built without installing a water treatment system as well. The size of the plant depends on the forecast wash volume. As a rule, portal systems have a service water supply of between 30 and 100 litres of treated water per vehicle wash, in car washes this can be up to 500 litres per wash.

A distinction is made between physical water treatment (filtration systems), which often only achieve optimum results by adding flocculation aids and disinfection agents or water treatment tablets, and biological water treatment, which does not require any chemical products at all. This decision also depends on the planned washing volume.

Basic information on fresh water, process water, wastewater treatment and permeate

The sole use of fresh water from the municipal or communal network is uneconomical and also ecologically questionable. It is better to convert the used wash water into so-called service water, i.e. treated water that may be used again for washing. For optimum washing and drying results, the pH value of the process water should be between 7-8.

Only when a certain load limit is reached does the process water become final wastewater and must be disposed of. The applicable legal regulations regarding the degree of contamination of the wastewater are decisive here.

A special case is the so-called permeate water (distilled water). This water, specially demineralised by reverse osmosis, is used for spotless rinsing, especially if the available fresh water contains a lot of lime.

Water purification and water recycling – Wwater treatment tablets and much more.

Water treatment plants basically have two important tasks for car wash operators. On the one hand, they should reduce the overall consumption of the plant by treating the wastewater, and on the other hand, they should treat the waste water to such an extent that the legal limit values are complied with. Decisive for the quality of the process water are the pH value as well as conductivity and water hardness, but also the concentration of suspended solids as well as the corrosive properties.

As an operator, you will recognise the decreasing quality of your water above all by the odour, increased staining of customer vehicles and increased soiling of the washing materials and system elements. The first reaction is usually to increase the dosage of detergent used, but it is more crucial to address the source of the problem. There are some welcome chemical helpers available for this purpose.

Sterilisers and flocculants for wastewater treatment

Odour, contamination and declining cleaning results indicate poor service water quality. Take countermeasures with disinfecting and flocculating agents.

Odour, contamination and declining cleaning results indicate poor service water quality. Take countermeasures with disinfecting and flocculating agents.

Depending on the goal of your water treatment in the respective step, it is also worthwhile to differentiate the applied chemical aid. Biocide-free products such as the Caramba disinfectant remove biological contaminants such as bacteria and fungi and thus primarily ensure a more pleasant odour of the service water.

In addition, the use of this product minimises the risk of the cleaning process being affected by bacteria. You can use the disinfectant directly in your system all the time. This way, your customers and employees will also benefit from fresher, cleaner service water.

The Caramba flocculant, on the other hand, is a product for direct water treatment and serves as a reaction agent for flocculation. The agent is an aqueous aluminium hydroxide chloride solution with cationic polymer content for the coagulation and flocculation of service and wastewater.

The product is used for flocculation of contaminants in wastewater in the pH range 6.5-8.5. The flocks formed can be easily sedimented or floated and then filtered off.

Unwanted water constituents such as oils, fats, waxes, surfactants, tar, petrol, resins as well as inorganic dirt are eliminated from the service water and the recycled water is again available for the respective process.

The flocculant can be used directly in the sludge trap. The functioning of the separation plant is thus significantly improved and optically clear water is available.

Would you like to benefit from Caramba’s many years of experience in operating your car wash?

You’d like a consultation at your site?